In purely environmental terms, Agra and the Taj Mahal have had their share of concerns and controversies, ranging from pollution of the Yamuna to discoloration of the much-venerated monument.

A new research by Centre for Science and Environment (CSE), the New Delhi-based think tank, has opened up a new front in the city’s struggle against environmental pollution and ecological mayhem.

Agra’s claim to fame also rests on the city being the largest footwear manufacturing hub in India. Catering to about 65 per cent of India’s domestic demand, the city churns out 0.9 to one million pairs of footwear every day.

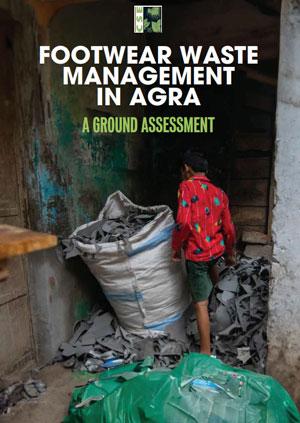

Such a scale of production comes with its own set of challenges – the city produces about 45 tonne of footwear waste in a day, says the assessment by CSE. This is in addition to the 978 tonne of municipal solid waste generated every day, comprising of wet, dry, domestic hazardous and sanitary wastes.

CSE recently released the study and its findings here at a stakeholder conference organised in association with the Agra Municipal Corporation.Agra has 6,821 footwear manufacturing units – both formal and informal.

Says Kuldeep Choudhary, programme officer and the lead author of the CSE report: “Typically, footwear waste includes a very diverse range of waste items from leather, textile (polyester, viscose), synthetic polymers (polyvinyl chloride, ethyl vinyl acetate (EVA), styrene butadiene rubber (SBR), polyurethane (PU) and thermoplastic elastomers), hazardous wastes (foam soaked in adhesive solution), cardboard, metal and fines. Of the total quantum of footwear waste generated, over 31 tonne per day is contributed by the formal manufacturing industries; more than 13 tonne comes from the informal manufacturers who run their businesses from homes.”

The CSE report says that AMC is able to collect about 57 per cent of the footwear waste generated by the home-based informal sector; the remaining 43 per cent is littered across the city in drains and open spaces or event burnt. The formal manufacturing units have reportedly tied up with formal and informal waste dealers and management professionals to manage their waste.

Choudhary points out: “The larger share of Agra’s footwear industry is informal in nature and operates under challenging conditions, but this presents a unique opportunity to uplift these communities. By providing financial aid, hands-on support in transitioning to sustainable practices, and raising awareness about the impact of poor waste management, we can foster positive change.”

Atin Biswas from CSE says: “Considering the scale of production and footwear waste generation in Agra, special mechanisms including additional funding and infrastructure must be provided to help the municipal corporation manage this waste. More research is needed to explore the recycling-reuse-repurpose potential of the footwear waste fractions to create a business ecosystem.”

Puran Dawar, president, Agra Footwear Manufacturing Export Chambers (AFMEC), said: “It is critical to understand the current methods of segregation, and design a collection system with support from the Agra Municipal Corporation. The cost of collection can be recovered by imposing applicable fees to footwear manufacturing units in Agra. The municipal corporation can also explore a mechanism if footwear waste could be purchased in bulk quantity for further and needful actions.”